Fully automated large part measurement system.

Ease-Of-Use

Inspection of a family of spun-formed components takes place from a single mouse click.

Accuracy

System achieves 0.015″ 2-sigma precision over a 12-foot (4 meter ) diameter.

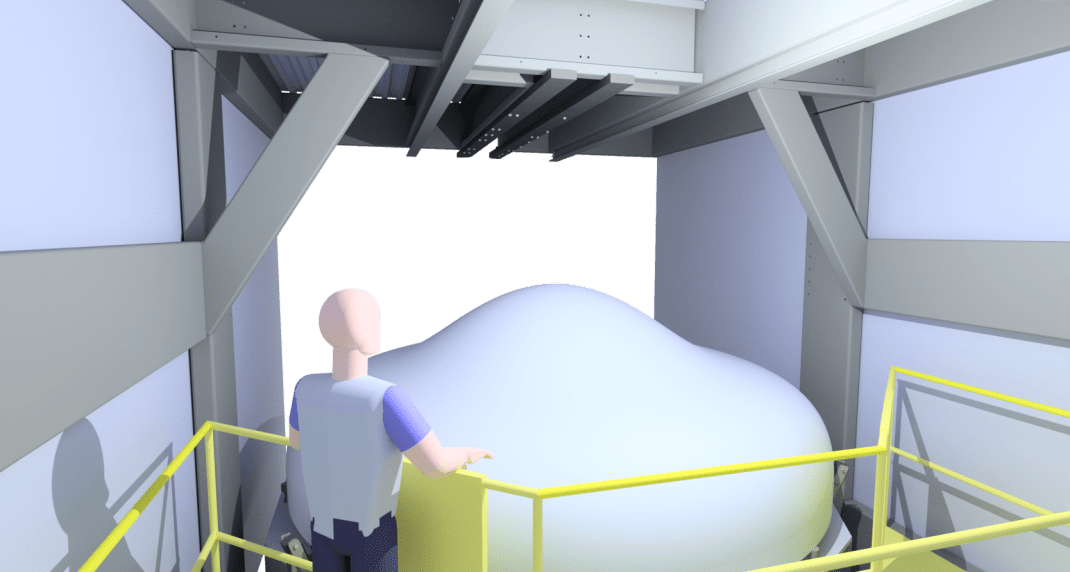

3D Projection of Color Map Deviations

As each part is inspected, the deviations from nominal (CAD) are projected directly on the part surface to illuminate pass/fail conditions. A digital copy of the color map is stored on the PC network.

Thickness and Profile Measurements

Measurement results show machining yield from spun component.

Part-Specific Programming

Datums, tolerances, and inspection criteria are automatically applied to each part during runtime.

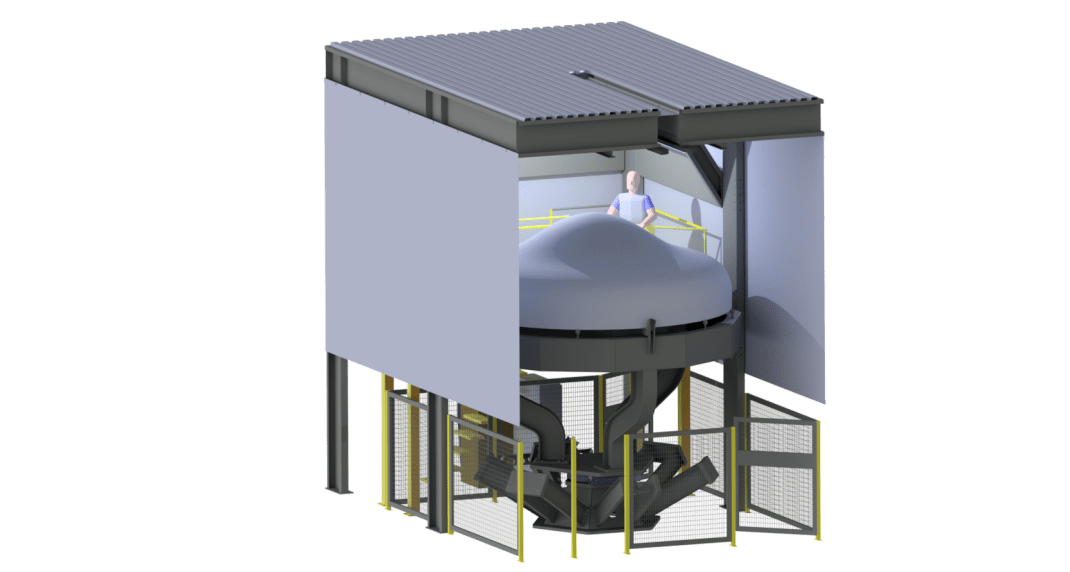

In-Process Measurement

Hardware integrated into the work environment ensures that the parts can be bought off prior to the machining process. Any marginal or out-of-tolerance conditions can be identified and corrected before machining begins.

Cycle Time

Cycle time including setup is reduced from hours to 15 minutes.